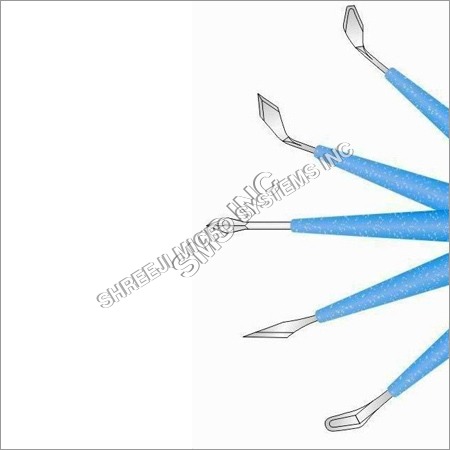

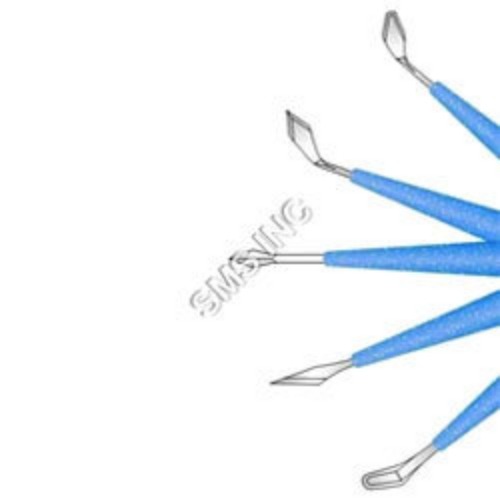

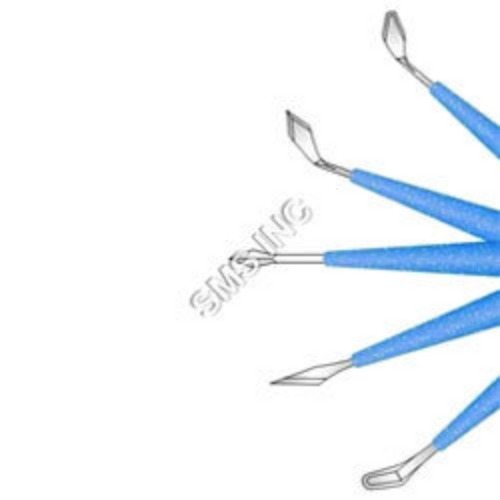

Ophthalmic Micro Blade

Price 45 INR/ Unit

Ophthalmic Micro Blade Specification

- Equipment Type

- Surgical Instrument

- Material

- Stainless Steel

- Condition

- New

- Operating Type

- Manual

- Driven Method

- Manual

Ophthalmic Micro Blade Trade Information

- Minimum Order Quantity

- 100 Units

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Units Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Ophthalmic Micro Blade

Features:

- Corrosion Resistance

- Durability

- Easy to handle

- High strength

- Stab Knives are heat-tempered to provide a strong, true point for easy penetration during initial stab incisio

- SMS-lance-15 Blade, Straight

- SMS-lance-30 Blade, Straight

- SMS-lance-45 Blade, Straight

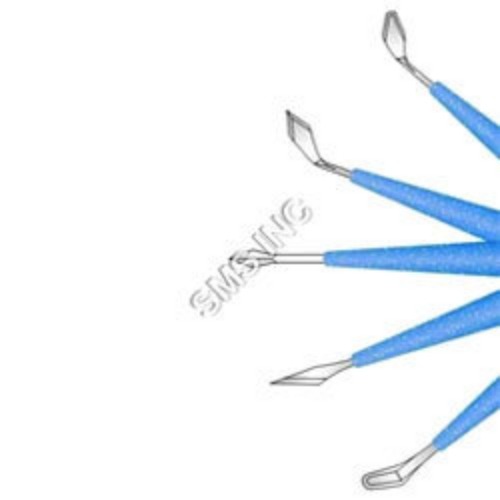

Standard Implant Knives - Straight

Specifications

Standard Implant Knives are designed to create a precise incision for lens insertion.

SMS-4.0,5.0mm,5.1mm,5.2 mm Straight/Angled Bevel up / down.

Precision Implant Knives - Straight

Specifications

Precision Implant Knives are designed to follow the slit blade incision easily while the cutting edges create a precise opening for lens insertion.

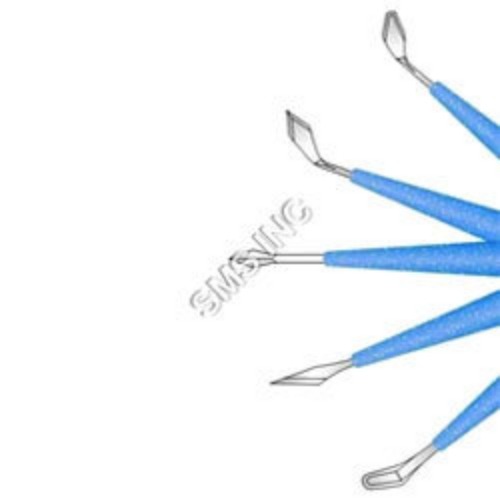

Slit Knives - Straight

Specifications

Precision Slit Knives penetrate easily while making an accurate width incision for optimal fit to the phacoemulsification tip.

Precision Implant Knives - Angled

Specifications

Precision Implant Knives are designed to follow the slit blade incision easily while the cutting edges create a precise opening for lens insertion.

Slit Knives - Double Bevel - Straight

Specifications

Double Bevel Slit Knives allow straight, smooth penetration without tissue drag.

- SMS-1.65 mm Straight/Angled Bevel up / down

- SMS-2.0 mm Straight/Angled Bevel up / down

- SMS-2.2 mm Straight/Angled Bevel up / down

- SMS-2.5 mm Straight/Angled Bevel up / down

- SMS-2.8 mm Straight/Angled Bevel up / down

- SMS-3.0 mm Straight/Angled Bevel up / down

- SMS-3.2 mm Straight/Angled Bevel up / down

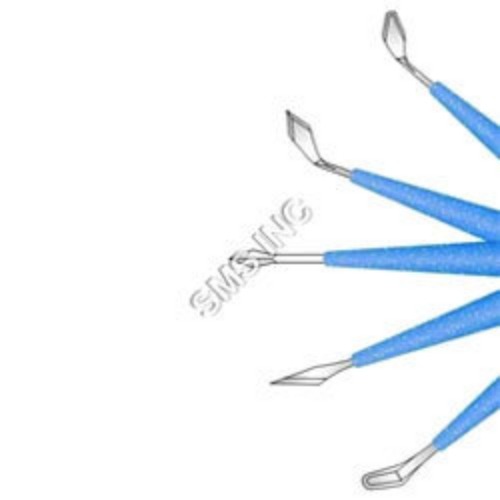

Crescent Design Knives - Straight

Specifications

Crescent Knives provide consistent sharpness, which nearly eliminates tissue drag. Ideal knives for creating a smooth scleral shelf to promote a self-sealing wound.

SMS-2.5mm,3.0mm-Straight / Angled Bevel up / down

Slit Knives - Single Bevel - Angled

Specifications

- SMS-1.65 mm Straight/Angled Bevel up / down

- SMS-2.0 mm Straight/Angled Bevel up / down

- SMS-2.2 mm Straight/Angled Bevel up / down

- SMS-2.5 mm Straight/Angled Bevel up / down

- SMS-2.8 mm Straight/Angled Bevel up / down

- SMS-3.0 mm Straight/Angled Bevel up / down

- SMS-3.2 mm Straight/Angled Bevel up / down

Vitrectomy MVR Knives

Specifications

Vitrectomy MVR Knives create small, precise access incisions which help prevent leakage around probes and other posterior segment instruments.

- SMS-19G, round shaft, double cutting edge

- SMS-20G, round shaft, double cutting edge

- SMS-24G, round shaft, double cutting edge

Superior Stainless Steel Quality

Our Ophthalmic Micro Blades are constructed from premium stainless steel, ensuring exceptional sharpness, corrosion resistance, and strength. This quality construction guarantees long-lasting performance and efficient sterilization, making them a preferred choice among medical professionals worldwide.

Manual Precision for Complex Procedures

Designed for manual operation, these surgical micro blades offer unparalleled control, making them ideal for the intricate demands of ophthalmic surgery. The blades ergonomic handle allows surgeons to perform precise and minimally invasive cuts, catering to a variety of eye surgeries.

FAQs of Ophthalmic Micro Blade:

Q: How is the Ophthalmic Micro Blade used during eye surgeries?

A: The Ophthalmic Micro Blade is manually operated to perform precise incisions in delicate eye tissues. Surgeons hold the blade by its ergonomic handle, ensuring a steady grip for controlled and accurate cutting during procedures such as cataract or corneal surgeries.Q: What are the main benefits of using a manual ophthalmic micro blade made of stainless steel?

A: Manual ophthalmic micro blades crafted from stainless steel offer superior sharpness, durability, and corrosion resistance. These attributes enable accurate incisions, easy sterilization, and repeated use without compromising instrument integrity.Q: When should a new ophthalmic micro blade be used in surgical procedures?

A: A new ophthalmic micro blade should be used whenever performing sterile surgical procedures to minimize infection risks and guarantee optimal cutting performance. Using a fresh blade for each surgery ensures the highest standards of safety and precision.Q: Where are these micro blades manufactured and exported from?

A: These ophthalmic micro blades are manufactured and exported from India by trusted exporters, manufacturers, and suppliers with adherence to international quality standards for surgical instruments.Q: What processes ensure the quality of the ophthalmic micro blade?

A: Each blade undergoes stringent manufacturing protocols, including quality checks for sharpness, material consistency, and sterilization. This rigorous process ensures each instrument meets global medical specifications required for ophthalmic surgery.Q: How does the manual driven method improve the surgical process?

A: The manual operation allows the surgeon to control the blades movement precisely, reducing the risk of accidental cuts and improving overall surgical outcomes. This is particularly advantageous for procedures requiring intricate dissection and fine motor skills.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ophthalmic Blade Category

Miniature Ophthalmic Blades

Price 200 INR / Unit

Minimum Order Quantity : 100 Units

Driven Method : Manual

Condition : New

Operating Type : Manual

Material : Stainless Steel

Lance Tip Blades

Price 35 INR / Unit

Minimum Order Quantity : 100 Units, ,

Driven Method : Manual

Condition : New

Operating Type : Manual

Material : Stainless Steel

Angled Ophthalmic Knives

Price 50 INR / Unit

Minimum Order Quantity : 100 Units

Driven Method : Manual

Condition : New

Operating Type : Manual

Material : Stainless Steel

Ophthalmic Knives

Price 55 INR / Unit

Minimum Order Quantity : 100 Units

Driven Method : Manual

Condition : New

Operating Type : Manual

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS